Electrical wire recycling represents a significant revenue opportunity for electricians, contractors, and demolition professionals who regularly handle copper wiring in their work. With copper consistently ranking among the most valuable recyclable metals, understanding proper wire recycling techniques and preparation methods can substantially impact project profitability while supporting environmental sustainability.

At Iron and Metals, we process substantial volumes of electrical wire from residential, commercial, and industrial sources throughout Colorado. Our experience has shown that contractors who understand wire types, preparation requirements, and pricing factors consistently achieve better returns than those who treat wire recycling as an afterthought.

This guide covers the essential information electricians and contractors need to maximize returns from wire recycling, including identification of different wire types, preparation techniques that improve pricing, and best practices for efficient collection and processing.

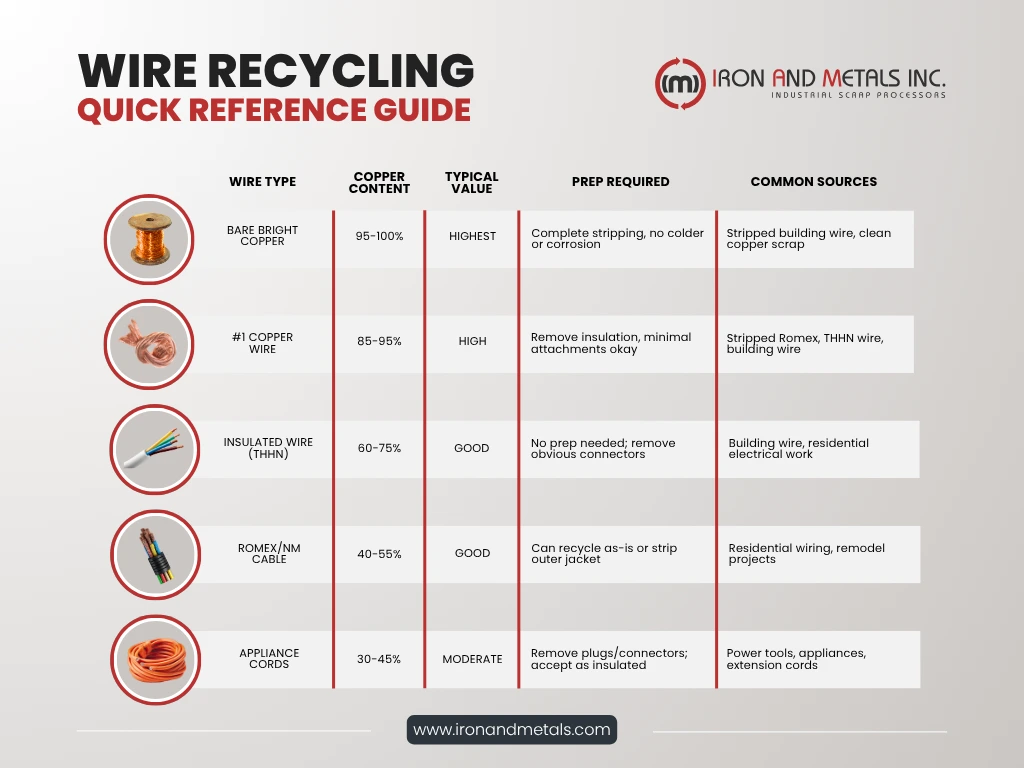

Electrical wire comes in numerous configurations, each with different copper content and recycling values:

Understanding these distinctions helps prioritize preparation efforts and set realistic expectations for recycling returns based on the wire types encountered in different projects.

Every electrical job produces wire worth recycling, sometimes more than you realize.

Residential projects like rewiring or renovations often generate plenty of scrap from materials such as Romex (NM cable), THHN wire, and older cloth-covered wiring. Kitchen and bathroom remodels, in particular, tend to include heavier-gauge wires that bring solid recycling returns.

Commercial jobs create a wider mix, from large feeder cables and control wiring to data cables. Office remodels and tenant improvements can yield large volumes of copper as entire systems get replaced.

Industrial sites are even more copper-rich. Three-phase power cables, motor leads, and other heavy-duty wiring contain a high percentage of valuable metal. When equipment is decommissioned or upgraded, those materials add up fast.

Demolition work can also uncover hidden value. Older buildings often have thick copper wire behind walls, in conduits, or throughout outdated infrastructure that’s easy to overlook.

And don’t forget appliances and equipment — things like washers, dryers, and HVAC units often contain wiring that’s quick to remove and easy to recycle.

Wherever you’re working, collecting and separating these wires can turn everyday job debris into extra income.

Keep in mind that not all wire is worth the same. Pricing depends on a few key factors that determine its grade and market value.

The biggest factor is copper content. Clean, bare copper wire (often called bare bright) is almost 100% copper and earns the highest price. Heavily insulated wire, on the other hand, might only be 30–40% copper by weight, which lowers its value.

Wire thickness, or gauge, also plays a role. Thicker wire is easier to process and can bring a slightly better rate, but thinner wire is still valuable when collected and sorted properly.

The type and amount of insulation affect how much copper is actually recoverable. For example, thin building wire holds more copper per pound than thick, heavily coated appliance cords.

Keeping your wire clean and free of contamination is another big factor. Remove any steel, connectors, or solder to avoid deductions as clean wire always earns more.

Finally, remember that copper prices change based on the global market. Staying aware of pricing trends (or checking in with the team at Iron & Metals) helps you decide the best time to bring in your scrap for the highest return.

Getting your wire ready before recycling can make a big difference in what you earn. Stripping off the plastic or rubber insulation can sometimes double the value of certain types of copper wire, but it’s only worth the effort if you’ve got the time or a good amount of material.

For contractors handling larger volumes, mechanical wire strippers are a great investment. They make it quick and easy to remove insulation and keep wires clean. It also helps to separate your wire by type (keeping bare bright copper apart from insulated or mixed wire, for example) so each grade gets priced at its full value.

Before dropping it off, cut away any steel ends, plastic connectors, or other attachments that could contaminate the copper. Keeping your wire separate from other metals like steel or aluminum ensures you get the best possible return.

For smaller jobs or limited wire quantities, it’s often fine to leave the insulation on and take the standard price. The key is knowing when the extra prep time will pay off and when it’s smarter to keep things simple.

The way you collect and store wire on the job can make a big difference in how efficiently you recycle it and how much you earn.

Use dedicated containers for wire instead of tossing it in with general debris. Five-gallon buckets, bins, or small barrels work great, depending on the size of the project. Whenever possible, separate wire by type during collection like heavy-gauge, building wire, and miscellaneous cords. This makes sorting faster later on.

Because copper has real value, keep your scrap secure, especially on long-term job sites. Theft can happen quickly, so store wire in a locked area or remove it from the site regularly.

In your truck, simple bins or buckets make it easy to collect wire throughout the day without losing material. Back at your shop, keep scrap in a dry, organized space to prevent corrosion or contamination. Secure storage also makes it easier to track what you’ve collected and when it’s time to bring it in.

If you handle multiple projects, consider tracking your scrap by job or date. It not only helps with business planning but also provides documentation if you need to verify proper disposal for permits or compliance.

Getting the best return from wire recycling is all about working smarter, not harder.

Start by focusing on wire that’s easy to collect and prepare: anything already pulled from conduit or disconnected is ready to recycle with minimal effort.

Whether or not you strip insulation depends on copper prices and your time. When the market is strong, stripping can pay off. When prices dip, you may earn more overall by keeping insulation on and saving the labor time.

It’s also worth waiting until you’ve got a decent load before making a trip to the recycler. Many contractors find weekly or monthly drop-offs strike the right balance between efficiency and storage space.

Building a relationship with your recycler pays off, too. At Iron & Metals, we reward regular customers with fair, transparent pricing and consistent service. Plus, our team can help you understand how current copper prices might affect your timing or preparation strategy.

If you’re working with other contractors or managing multiple sites, combine your scrap when possible. Larger loads can sometimes qualify for better pricing, helping you make the most of your material.

Wire recycling is straightforward, but safety should always come first.

Before removing any wire, make sure power is fully disconnected - even low-voltage systems can cause shocks. Wear cut-resistant gloves to protect your hands from sharp edges, stripped wire, or frayed insulation.

Be mindful of weight when handling large-gauge wire or big bundles. Use proper lifting techniques or equipment to avoid back injuries.

If you’re using mechanical strippers, make sure the area is well-ventilated and clear of flammable materials. These tools can generate heat and friction, so have fire safety equipment nearby just in case.

And when working in older buildings, stay alert for hazardous materials like asbestos or lead. If you suspect contamination, stop and get professional guidance before proceeding.

Iron & Metals strives to make wire recycling simple, transparent, and profitable for Colorado electricians and contractors.

Our pricing reflects current copper market values, and we always explain grading standards so you know exactly how your material is valued. With no-appointment drop-offs, you can swing by between jobs or at the end of the day — our drive-on scales mean quick weighing and fast payment.

Not sure what type of wire you have? Our experienced team can help identify it and suggest ways to improve your returns through simple prep steps.

For contractors with consistent volumes, we offer volume pricing programs that reward regular recycling. For larger projects, we provide roll-off containers delivered directly to your job site or shop, making collection easy and efficient.

We also provide detailed receipts and weight tickets to support your business records, and documentation for sustainability or client reporting if needed.

We’re here to support your success — not just with great pricing, but with honest communication and reliable service you can count on.

Wire recycling isn’t just good for the environment, it’s good business. By collecting and sorting scrap efficiently, making smart prep decisions, and working with a trusted recycler, electrical contractors can turn leftover wire into a steady source of revenue.

The best results come from keeping things consistent: use dedicated containers, stay organized, and visit your recycler regularly. These small habits add up to big returns over time.

As copper demand remains strong and sustainability becomes even more important in construction, recycling scrap wire will continue to be a key part of running a profitable, responsible electrical business.

Ready to make the most of your wire recycling? Contact Iron & Metals today to check current prices, get prep tips, or set up container service for your next project.