Implementing an effective metal recycling program requires more than just good intentions - it demands the right equipment to collect, sort, and transport your scrap materials efficiently. Metal recycling containers form the foundation of any successful recycling operation, whether you're a contractor managing job site waste, a manufacturer dealing with production scrap, or a business looking to implement sustainable practices.

At Iron and Metals Inc, we've provided metal recycling containers to Colorado businesses and residents for over six decades. Our experience has shown that choosing the right containers significantly impacts both the success of your recycling program and the value you receive from your scrap materials. The wrong container choice can lead to contamination, inefficient collection, safety hazards, and reduced returns on your recyclable metals.

Understanding the various types of metal recycling containers available and matching them to your specific needs ensures maximum efficiency, safety, and profitability from your recycling efforts.

Understanding Metal Recycling Container Types

Roll-Off Containers

Roll-off containers represent the most versatile and widely used solution for metal recycling programs across various industries. These large, rectangular containers are delivered and picked up using specialized trucks equipped with hydraulic systems that allow for easy placement and removal.

Standard Roll-Off Sizes:

- 10 Yard Containers: Ideal for small contractors or businesses with moderate scrap generation

- 20 Yard Containers: Perfect for medium-sized operations or construction projects

- 30 Yard Containers: Suitable for larger construction sites or manufacturing facilities

- 40 Yard Containers: Designed for high-volume operations or major demolition projects

Roll-off containers excel in situations requiring bulk collection of mixed metals or where space allows for larger equipment. Their open-top design facilitates easy loading of irregularly shaped metal items, while their substantial capacity reduces the frequency of pickups needed.

Lugger Containers

Lugger containers offer a more compact alternative to traditional roll-offs while maintaining professional-grade capacity and durability. These containers work with specialized lugger trucks that use a different loading mechanism than roll-off systems.

Lugger containers typically range from 6 to 40 cubic yards and provide advantages in tight spaces where roll-off trucks cannot maneuver effectively. They're particularly useful for urban locations, confined job sites, or facilities with overhead restrictions that prevent roll-off container placement.

Compactor Containers

For businesses generating large volumes of lighter metal scrap, compactor containers provide space-efficient collection solutions. These systems compress materials as they're loaded, allowing for more material per pickup and reducing collection frequency.

Compactor containers work particularly well for:

- Beverage can collection programs

- Light sheet metal and aluminum scrap

- High-volume but low-density metal waste streams

- Situations where space is limited but volume is high

Specialized Container Options

Certain metal recycling applications require containers designed for specific materials or handling requirements.

- Open-Top Trailers: These 40-foot trailers provide maximum capacity for lightweight, bulky materials like aluminum siding, gutters, or large structural components.

- Flatbed Trailers: Ideal for heavy, dense materials like steel beams, machinery, or equipment that requires crane loading and unloading.

- Cargo Container Conversions: Modified shipping containers offer secure, weather-resistant storage for valuable metals or materials requiring protection from theft or environmental exposure.

Container Size Selection Guidelines

Assessing Your Volume Needs

Proper container sizing requires careful assessment of your metal generation patterns, storage capabilities, and pickup frequency preferences.

- Daily Generation Analysis: Track your metal waste generation over several weeks to understand typical daily and weekly volumes. Consider seasonal variations that might affect generation rates, particularly for construction-related businesses.

- Storage Space Evaluation: Measure available space for container placement, considering access requirements for delivery and pickup trucks. Account for overhead clearances, turning radius needs, and any restrictions on container placement timing.

- Weight Considerations: While containers have volume ratings, weight limits often determine actual capacity for metal recycling. Dense metals like steel and iron may reach weight limits before filling container volume, while lighter materials like aluminum may fill volume before reaching weight restrictions.

Small-Scale Operations (1-10 Cubic Yards)

Businesses and contractors with modest metal recycling needs often find smaller containers provide the right balance of capacity, cost, and space requirements.

Typical Applications:

- Small construction contractors

- Automotive repair shops

- Small manufacturing operations

- Retail businesses with periodic equipment replacement

These operations benefit from more frequent pickups with smaller containers rather than waiting to fill larger units, which can tie up valuable space and create safety or security concerns.

Medium-Scale Operations (15-30 Cubic Yards)

Mid-sized operations typically require containers that balance substantial capacity with reasonable space requirements and pickup frequency.

Typical Applications:

- General contractors and construction companies

- Medium-sized manufacturing facilities

- HVAC contractors with regular equipment replacement

- Multi-location businesses consolidating scrap collection

Medium-scale operations often benefit from establishing regular pickup schedules that align with their project cycles or production schedules.

Large-Scale Operations (40+ Cubic Yards)

High-volume metal recycling operations require maximum-capacity containers and specialized handling procedures to manage substantial material flows efficiently.

Typical Applications:

- Major construction and demolition projects

- Large manufacturing facilities

- Scrap metal dealers and processors

- Municipal recycling programs

Large-scale operations often utilize multiple containers to segregate different metal types or maintain continuous collection capability while containers are being exchanged.

Material-Specific Container Considerations

Ferrous Metal Collection

Steel and iron scrap present unique challenges due to their density and weight. Container selection for ferrous metals must account for weight limitations and structural requirements.

Container Features for Ferrous Metals:

- Reinforced floors and walls to handle heavy materials

- Lower profile designs to facilitate loading of dense items

- Adequate weight capacity ratings

- Easy access for magnetic separation if needed

Loading techniques for ferrous metals should distribute weight evenly and avoid concentrated loads that could damage containers or create safety hazards during transport.

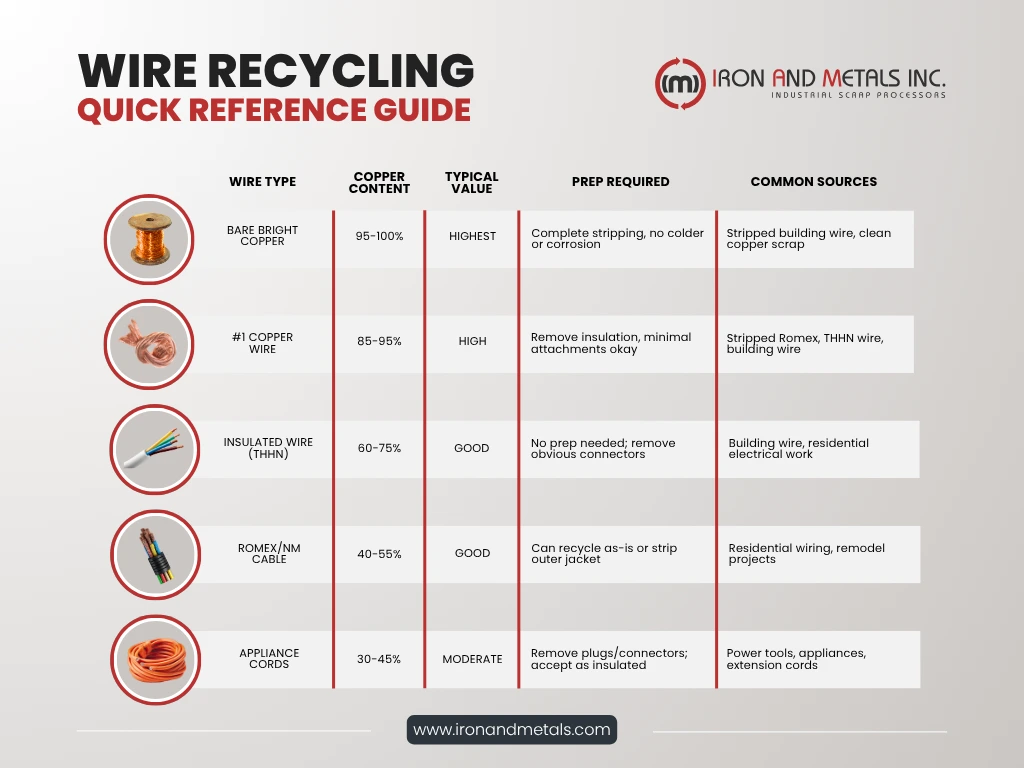

Non-Ferrous Metal Collection

Aluminum, copper, brass, and other non-ferrous metals often require different container approaches due to their higher values and theft potential.

Security Considerations:

- Lockable lids or secure container designs

- Strategic placement away from public access

- Regular pickup schedules to minimize accumulation

- Proper documentation and tracking procedures

Non-ferrous metals may also require separation from ferrous materials to maintain premium pricing, necessitating multiple containers or internal division systems.

Mixed Metal Programs

Many operations generate various metal types that can be collected together initially and sorted later. Mixed metal collection requires containers that accommodate different material characteristics while maintaining segregation when necessary.

Design Features for Mixed Collections:

- Adequate capacity for various material densities

- Easy access for loading different sized items

- Compatibility with sorting procedures at processing facilities

- Clear labeling to prevent contamination with non-metals

Safety and Compliance Features

OSHA and DOT Requirements

Metal recycling containers used in commercial and industrial settings must comply with various safety regulations governing workplace safety and transportation.

Key Safety Requirements:

- Proper weight distribution and tie-down points

- Adequate structural integrity for intended loads

- Clear marking and identification systems

- Compliance with transportation weight limits

Understanding these requirements helps ensure your container selection supports safe operations while meeting regulatory obligations.

Environmental Protection

Proper container design and usage help prevent environmental contamination and support sustainable recycling practices.

Environmental Considerations:

- Leak-proof construction for containers holding materials with residual fluids

- Weather protection for materials sensitive to moisture or corrosion

- Proper drainage systems to prevent water accumulation

- Contamination prevention through appropriate covers and access controls

Security and Theft Prevention

Metal theft represents a significant concern for recycling programs, particularly for high-value non-ferrous metals.

Security Features:

- Locking mechanisms and secure closure systems

- Strategic placement in well-monitored areas

- Lighting and surveillance considerations

- Regular pickup schedules to minimize accumulation

Cost Considerations and Budgeting

Rental vs. Purchase Options

Most metal recycling container programs operate on rental basis, though purchase options exist for high-volume, long-term applications.

Rental Program Advantages:

- Lower initial investment requirements

- Included maintenance and repair services

- Flexibility to adjust container sizes as needs change

- Professional pickup and delivery services

Purchase Considerations:

- Higher upfront costs but potential long-term savings

- Maintenance and repair responsibilities

- Storage requirements when containers aren't in use

- Transportation and logistics management

Pickup Frequency Impact

Container size selection directly affects pickup frequency, which influences both operational efficiency and total program costs.

Factors Affecting Pickup Frequency:

- Container capacity relative to generation rates

- Storage space limitations

- Material value and security concerns

- Seasonal variations in scrap generation

- Revenue considerations from recycling revenue

Hidden Costs and Fees

Understanding the complete cost structure helps ensure accurate budgeting for metal recycling container programs.

Potential Additional Costs:

- Delivery and pickup fees beyond standard service areas

- Overage charges for exceeding weight limits

- Contamination fees for non-metallic materials

- Special handling fees for hazardous materials

- Permit fees for container placement in public areas

Implementation and Setup Process

Site Preparation Requirements

Proper site preparation ensures safe, efficient container placement and pickup operations. The location should be a level, stable surface capable of supporting loaded containers with adequate access for delivery and pickup vehicles. Make sure there is enough overhead clearance for container loading and unloading and that local zoning and permit requirements are followed and adhere to compliance standards.

Consider seasonal access issues such as snow removal, drainage, and ground stability that might affect container operations throughout the year.

Operational Procedures

Establishing clear procedures for container usage maximizes efficiency and value while maintaining safety standards. This includes following proper loading procedures (balanced weight, separating metals, following safety rules, and documenting loads) and ongoing monitoring (inspections, contamination prevention, security measures, and communication with service providers) to stay on top of maintenance schedules.

Training and Education

Successful metal recycling container programs require proper training for all personnel involved in materials handling and container operations.

Training Topics:

- Safe loading and handling techniques

- Material identification and segregation

- Container capacity and weight limitations

- Emergency procedures and incident reporting

- Environmental compliance requirements

Working with Container Service Providers

Selecting the Right Provider

Choosing an appropriate container service provider significantly impacts program success and operational efficiency.

Provider Selection Criteria:

- Container inventory and size options

- Service area coverage and response times

- Pricing structure and transparency

- Environmental certifications and compliance

- Customer service and communication capabilities

Service Level Agreements

Clear service agreements help ensure expectations are met while providing flexibility for changing needs.

Key Agreement Elements:

- Container specifications and capacity limits

- Pickup schedules and flexibility options

- Pricing structure including all fees and charges

- Performance standards and response times

- Termination and modification procedures

Communication and Coordination

Effective communication with service providers ensures smooth operations and helps resolve issues quickly.

Communication Best Practices:

- Establish clear points of contact for both routine and emergency situations

- Maintain regular communication about changing needs or requirements

- Document any issues or concerns promptly

- Provide feedback on service quality and suggestions for improvement

Maximizing Value from Container Programs

Contamination Prevention

Keeping non-metallic materials out of metal recycling containers is essential for protecting material value and preventing costly processing issues. Common sources of contamination include plastic components attached to otherwise recyclable metal items, wood, concrete, and other types of construction debris.

Hazardous materials such as batteries or electronic devices also pose risks if mistakenly placed in metal containers. Even food waste or other organic materials can cause problems, leading to spoilage, odors, and compromised recyclability.

Establishing clear guidelines and training programs helps minimize contamination while maximizing the value of recycled materials.

Optimization Strategies

Continuous improvement strategies help optimize container programs over time. Regular reviews of container sizes and pickup frequencies can prevent both overflows and underutilization, ensuring that resources are used efficiently. Analyzing material flows and seasonal patterns provides insights into peak demand periods, allowing for proactive adjustments.

Organizations should also evaluate their separation and sorting procedures to confirm that they are keeping different types of metals cleanly divided. Finally, staying current on container technologies and design improvements can open new opportunities to enhance efficiency, safety, and cost-effectiveness.

Performance Monitoring

Tracking key metrics helps identify opportunities for improvement and demonstrates program value. Important indicators include material recovery rates and contamination levels, which show how effectively the system is working. Container utilization efficiency and cost per ton of processed material provide additional insights into operational performance.

Revenue generated from recycled materials can be measured alongside employee safety and incident rates to give a comprehensive view of program success. By consistently reviewing these metrics, companies can fine-tune their recycling strategies, reduce risks, and maximize returns.

Future Trends and Innovations

Technology Integration

Emerging technologies are beginning to transform metal recycling container operations through improved monitoring and efficiency.

Technology Trends:

- RFID tracking for container location and utilization monitoring

- Weight sensors for optimizing pickup schedules

- Mobile apps for scheduling and communication

- GPS tracking for logistics optimization

Sustainability Enhancements

Growing emphasis on environmental sustainability is driving innovations in container design and operations.

Sustainability Improvements:

- More efficient container designs reducing transportation impacts

- Enhanced sorting capabilities reducing contamination

- Integration with circular economy principles

- Improved materials recovery and processing efficiency

Colorado's leadership in environmental sustainability makes it an ideal market for implementing advanced metal recycling container programs that support both economic and environmental objectives.

Whether you're starting a new recycling program or optimizing an existing operation, choosing the right metal recycling containers forms the foundation of success. The key lies in matching container specifications to your specific needs while maintaining flexibility to adapt as your program evolves.

Ready to implement or upgrade your metal recycling container program? Contact Iron and Metals Inc today to discuss container options, sizing recommendations, and service plans tailored to your specific requirements.

Our decades of experience in Colorado's recycling market can help you design a container program that maximizes efficiency, value, and environmental benefits.